Air Management for Baking and Food Processing Facilities

The purpose of this “brief” is to share the “big picture” providing accurate information to assist facility engineers with their decision making process. There is no one-size-fits-all solution applicable to all facilities. This brief will examine pros and cons by first asking “why” are we considering a new system. Then we may determine “what” the overall project objectives are. Finally “how” these objectives can be balanced with available capital and ROI which may include removing some false perceptions.

Industrial Ventilation Systems for Baking and Food Processing Facilities

Food production facilities require special attention to various facets including occupant comfort, heat stress, air filtration, building pressurization to prevent infiltration of insects, molds and other particulates as well as providing airflow which promotes efficient process equipment operations. Energy costs associated with these systems can represent a significant hidden portion of annual utility costs and poorly designed systems may add to this expense many times over in addition to food safety, sanitation, and maintenance concerns. For more information on our industrial ventilation systems or an audit performed at your facility please contact us.

Spiral Product Cooling Systems

Our self-contained environmental system engineered for bread cooling applications manages temperature, humidity, and air movement providing consistent conditions. Food safety is enhanced through air filtration removing greater than 90% of mold spores, and pressurization control preventing contamination from infiltrating the enclosure and landing on unprotected product. Considering baked products spend more of their time exposed to atmosphere during the cooling process these measures help provide consistent quality product, reduced mold complaints, and less waste. Our systems achieve energy savings ranging from 50% to 90% compared to typical refrigeration systems and frequently even cost less to operate than ambient coolers using exhaust fans and make up air. A 2-Line high speed Bread/Roll plant can exceed $200,000 per year in savings.

EPI-Vision Environmental Monitoring and Verification System

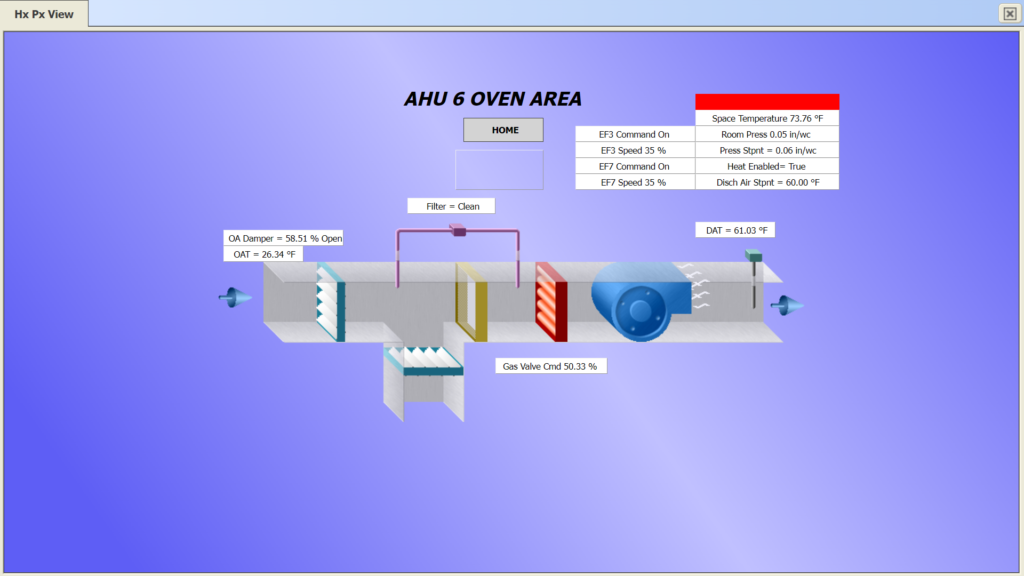

The new EPI-Vision is a remote monitoring and verification system which provides real time visibility of key Food and Occupant Safety Environmental Performance Indicators (EPI). When outside established parameters, EPI-Vision provides notifications which may directly impact Food Safety, Workers Heat Stress, and Product Quality.

Cleanrooms for Baking and Food Processing Facilities

There has been a significant push the past several years to increase Food Safety and Quality through improvement of environmental conditions inside wholesale baking facilities. Measures have focused on proper building pressurization and upgrading air filtration to prevent molds and insects from entering process areas. While we agree these measures are extremely important and positive first steps – there are other critical variables which must be considered. A food processing facility is a dynamic and interconnected environment. Over the years enhancements have been made while the emphasis has remained the same; to provide the three “P’s” consisting of a Predictable – Protected – Performance enhanced environment which supports your efforts in creating the perfect product.