The Scavenger is a modular waste heat recovery system developed to provide a lower initial cost while still providing all the benefits of our workhorse Sustainable Waste Heat Management System.

Developed for use primarily in applications without oxidizers, Scavenger is a packaged system capable of local installation or available as part of a turnkey solution. Systems are capable of remote monitoring allowing support at any time, in any location throughout the world. Reporting is available to measure energy saved and provide verification the system is operating to performance specifications

Recycle Waste Steams

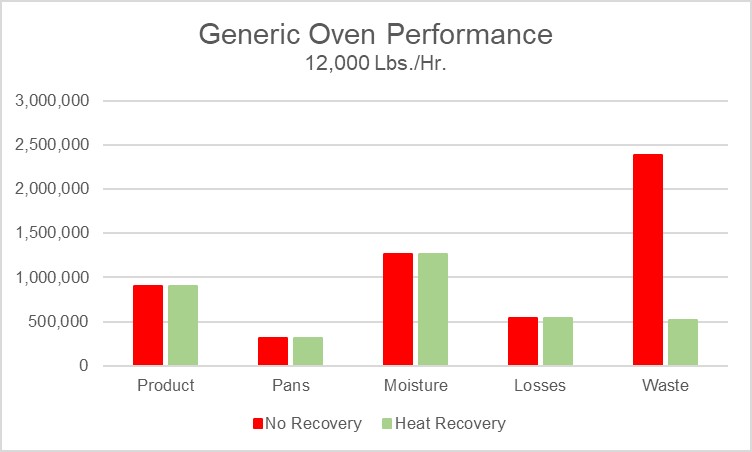

Bakeries have the unique ability to capture and repurpose their primary thermal waste stream for process. A single oven can provide the energy equivalent of an almost 1-acre solar field, at a fraction of the cost. End uses include Proofers, CIP, Water Heating, Basket, Pan Washing, and feedwater pre-heat. An optional condensing gas heat exchanger can double recoverable energy by capturing latent heat (moisture) from bake-out.

Modular Design

Modular design provides for a phased installation reducing initial investment. Systems may be installed when existing lines are upgraded or boilers require replacement. If existing boilers are being eliminated, backup thermal fluid heaters may be installed for cold start and high demand provisions. In facilities where conventional boilers are being retained, Scavenger is capable of integration into the existing system. Part of our Guaranteed Solutions, the modular and scalable Scavenger system provides a value oriented first step on your “Pathway to Sustainability”.

Recycling Waste Streams is “Double Green”

Air Management Technologies developed our first bakery waste heat recovery system over 20 ago as a solution to high natural gas prices using technology to transform oven exhaust into thermal energy.

These systems demonstrated their process capabilities and exceptional reliability in climates ranging from 100F to –40F. Additional innovations include the ability to simultaneously generate hot thermal energy and low temperature refrigeration. Larger facilities typically exceed $200,000 in annual savings along with over 1,000 tons of greenhouse gas reduction.

Why Scavenger?

Our heat recovery systems cost about the same as a central boiler system in a new facility while providing an immediate return on investment. Existing facilities however face roadblocks to achieving the same immediate ROI. The past decade’s very low natural gas prices along with a lack of capital avoidance (unless boilers required replacement) hindered some bakeries from implementing our proven technologies. Scavenger is our engineered response to provide a lower capital / high ROI in existing facilities. The modular design also affords Original Equipment Manufacturers the opportunity to offer our systems directly to their end users as a “factory” package.

With the return of high energy prices, now may be the best time to explore our proven heat recovery technologies.